- 日本語

- English

We would like to check all the speakers at the rated input or at the input level close to actual use. However, considering the health risk of the inspectors, it is not a practical solution to continuously check the sound pressure of over 100 dB by listening test.

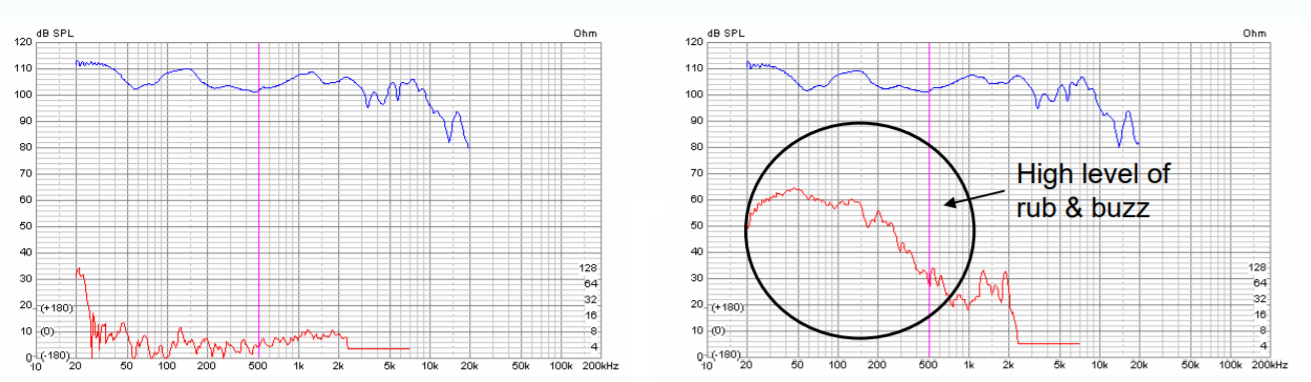

For this reason, ETANI has been promoting automatic inspection on production lines for more than 30 years, and has established a high-precision inspection method that incorporates inspection items such as our proprietary “Rub & Buzz” technology and limit control judgment. Even with loud sound levels and other test items that are too harsh for humans, we can provide stable test results by simply inputting simple condition settings into the automatic testing machine.

We encourage you to consider the introduction of automatic inspection machines from ETANI that ensure the continuous accuracy of inspections and avoid health risks to inspectors. The following is an introduction to the lineup of automatic inspection machines of ETANI.

The automatic inspection machine automatically starts the inspection when the signal from the PLC that the speaker is set in the anechoic chamber is received, and repeats the inspection by the cycle of transmitting the inspection result and the signal of the end when the inspection is finished, so the inspection booth can be operated unattended. We also have a wide range of microphones for various measurement applications, so we would appreciate it if you could contact us for any questions, including questions about combination devices.

High precision: Abnormal sounds can be detected at levels -80 dB or more below the SPL.

High-speed inspection: A maximum of 9 items (Frequency response, SPL, impedance, phase, distortion level, abnormal sound, etc.) can be measured with a sweep of 1 sec at a time. Multifaceted performance management is possible by combining measurement items with multiple sweeps with different input levels.